When you want to protect or decorate metal parts, two popular choices exist. They are powder coating and Cerakote. Both can make your items look good and last longer. But they work in different ways. This article will explain the differences clearly. By the end, you will know which one fits your needs best.

Credit: www.youtube.com

Credit: www.westmicerakote.com

What Is Powder Coating?

Powder coating is a way to paint metal using dry powder. This powder is made from tiny plastic particles. These particles stick to metal when you spray them with an electric charge. After spraying, the metal goes into a hot oven. The heat melts the powder and forms a hard coat.

This coat is thick and strong. It protects metal from scratches, rust, and weather. Powder coating is often used on big items. Examples include car parts, metal furniture, and playground equipment.

Key Features Of Powder Coating

- Thick Layer: The coat is heavy and strong.

- Durable: It resists dings and rough use well.

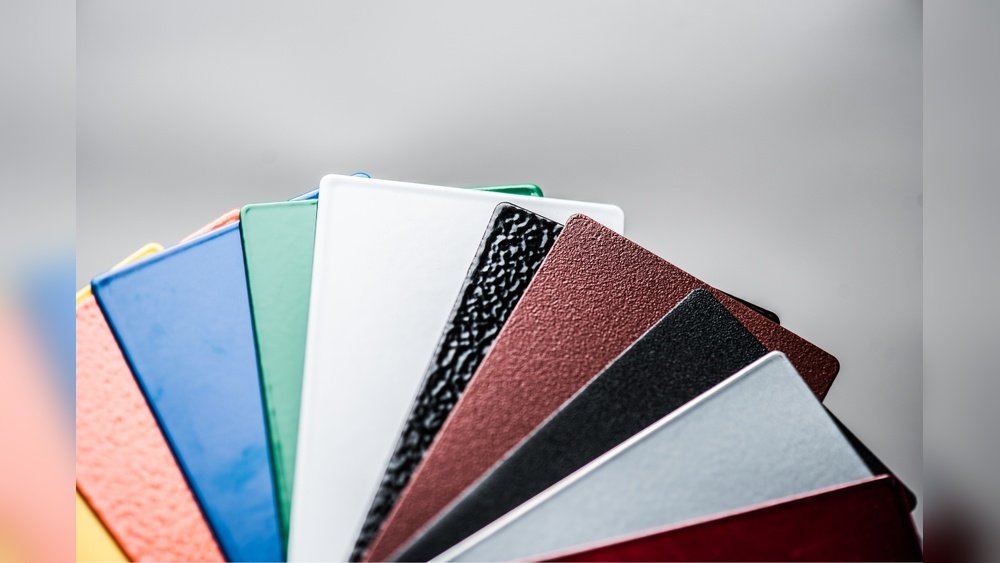

- Wide Colors: Many colors and finishes are available.

- Eco-Friendly: It has fewer harmful fumes than paint.

What Is Cerakote?

Cerakote is a special type of paint. It is ceramic-based and made to protect metal. It comes as a thin liquid that you spray on parts. Then, the part is baked at a lower temperature than powder coating. This heat makes the Cerakote hard and strong.

Cerakote is very thin. It does not cover fine details or change the shape. It sticks well to many materials, like metal, plastic, and even wood. Cerakote is popular for things that need precise protection, like guns and knives.

Key Features Of Cerakote

- Thin Layer: Keeps all details clear and sharp.

- Heat Resistant: Can handle high temperatures well.

- Chemical Resistant: Protects against oil, acids, and solvents.

- Wide Range of Uses: Works on many materials.

Comparing Powder Coating and Cerakote

| Feature | Powder Coating | Cerakote |

|---|---|---|

| Layer Thickness | Thick and heavy | Very thin and light |

| Durability | Strong against dings and scratches | Very resistant to chemicals and heat |

| Color Options | Many colors and finishes | Fewer colors but smooth finish |

| Material Compatibility | Mostly metals | Metals, plastics, wood, and more |

| Application | Sprayed as powder, then baked | Sprayed as liquid, then baked |

| Cost | Usually less expensive | Typically more expensive |

| Best Use | Large items needing thick protection | Small, precise parts needing chemical resistance |

Which One Should You Choose?

The best choice depends on what you want to protect or decorate. Here are some simple tips.

Choose Powder Coating If:

- You want a thick, tough coat for big items.

- You want many colors and textures to pick from.

- Your item will face rough use or outdoor weather.

- You want a cheaper option that still looks good.

Choose Cerakote If:

- You need a very thin coat that keeps details clear.

- Your item will face chemicals, heat, or oil often.

- You want to coat plastic, polymer, or unusual materials.

- You want a smooth, refined finish with strong protection.

Examples of Use

Let’s see where each coating is often used.

| Powder Coating | Cerakote |

|---|---|

| Metal outdoor furniture | Firearms and gun parts |

| Car wheels and frames | Knives and blades |

| Playground equipment | Sporting gear parts |

| Architectural metal pieces | Plastic gun parts |

Pros and Cons

Powder Coating Pros

- Strong and thick protection.

- More affordable for large jobs.

- Many colors and finishes.

- Good for outdoor use.

Powder Coating Cons

- Layer can hide small details.

- Not good for tight-fitting parts.

- Can chip with heavy impact.

Cerakote Pros

- Very thin, keeps details sharp.

- Resists heat and chemicals well.

- Works on many materials.

- Smooth, attractive finish.

Cerakote Cons

- More expensive than powder coating.

- Fewer color choices available.

- Not easy to find local shops.

How Are They Applied?

Both coatings need special tools and ovens. But the process differs.

Powder Coating Process

- Clean the metal part well.

- Spray powder using an electrostatic gun.

- Place part in oven to melt powder.

- Cool the part before use.

Cerakote Process

- Clean and prepare the surface.

- Spray Cerakote liquid evenly.

- Bake the part at lower heat.

- Cool and inspect for quality.

Summary

Powder coating and Cerakote both protect and beautify metal parts. Powder coating is thick and tough. Cerakote is thin but very strong against chemicals and heat. Powder coating costs less and offers many colors. Cerakote is more expensive but works on more materials.

Use powder coating for large, rough-use items. Use Cerakote for small, precise parts needing chemical or heat resistance. Think about what you want to protect. Choose the coating that fits your needs best.

Now you know the difference between powder coating and Cerakote. This will help you make smart choices for your projects.

Frequently Asked Questions

Is Cerakote Better Than Powder Coat?

Cerakote excels in thin, durable, heat- and chemical-resistant coatings for precision parts. Powder coat suits thick, impact-resistant, cost-effective finishes on larger items. Choose based on your specific needs; neither is universally better.

What Are The Downsides Of Cerakote?

Cerakote is typically more expensive and offers fewer color options than powder coating. It requires professional application, which can be hard to find locally.

What Are The Disadvantages Of Powder Coating?

Disadvantages of powder coating include a thicker finish that can obscure fine details and affect fitment. It may chip or scratch under heavy impact. Not suitable for tight-tolerance parts. Color options are wide but less precise than Cerakote. Requires curing ovens, limiting application flexibility.

Which Is Better, Powder Coating Or Ceramic Coating?

Cerakote suits high-precision, heat-resistant needs with a thin, durable finish. Powder coating excels in cost-effective, impact-resistant applications. Choose based on your project’s requirements and material type.

What Is The Main Difference Between Powder Coating And Cerakote?

Powder coating uses thick, baked-on powder; Cerakote is a thin, sprayed ceramic finish.

Which Coating Is Better For High-heat Resistance?

Cerakote resists heat better, making it ideal for firearms and engines.

When you purchase a product through Amazon links on carsolutionpro.com, we may earn a small commission at no extra cost to you. This helps support the site and keep our content free. As an Amazon Associate, we earn from qualifying purchases made through our links.